-

-

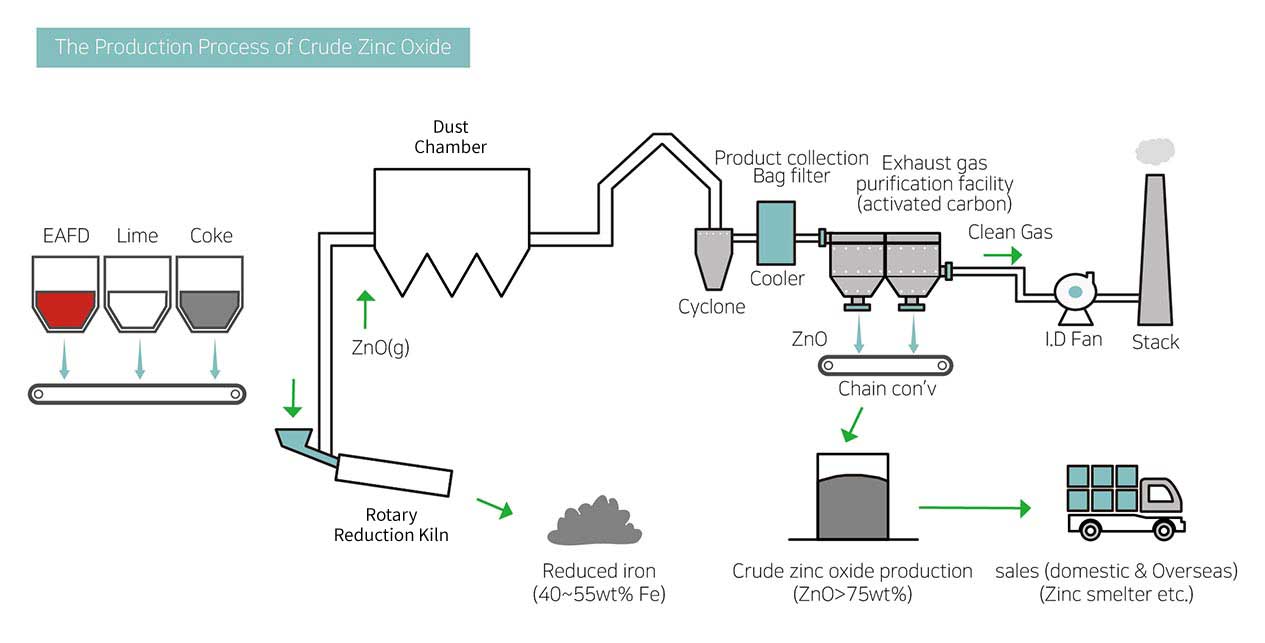

Crude Zinc Oxide Production

The our process of separating and correcting crude zinc oxide from by-products(steel dust, etc.) containing Zinc, which is consists of a variety of efficient and eco-friendly cutting-edge element technologies based on the Waelz Kiln Reduction process. When electric arc furnace dust, which is a designated waste, is subjected to our zinc seperation and collection process, the zinc component is converted into Crude Zinc Oxide, and the iron component is converted into reduced iron containing about 40 to 55wt% Fe which is used as a raw material for producing Iron & steel, aggregate and concrete products.

In this way, our advanced production technology of crude zinc oxide has played a key role not only in the domestic steel dust resource industry of the present, but also of the future.

We have been stably acquiring steel dust with a long-term supply contract from diverse companies including Hyundai Steel Co., Ltd.